1. Multifunctional polymer nanocomposites

The inclusion of nanoparticles into polymer matrix to produce nanocomposites has extensively been implemented in an attempt to enhance the physical and chemical properties of polymers. The full potential of such strategy can only be realised by an essential understanding of the relationship between processing-morphology-structure and final properties of the system.

Over the last years, we have fabricated advanced materials with different polymer matrices for specific applications. We work with several nanoparticles, laminar silicates, ceramic, carbon nanotubes or graphene, which are synthetized and functionalised in our laboratory.

The group has an ample experience in the processing and characterization of composite materials with different matrices: thermoplastics, thermosets, elastomers and biomaterials.

More details

- Graphene filled polymer nanocomposites

R. Verdejo, M. M. Bernal, L. J. Romasanta, M.A. Lopez-Manchado

Journal of Materials Chemistry 21, 3301-3310 (2011) - Recent advances in clay/polymer nanocomposites

N. Bitinis, M. Hernández, R. Verdejo, J.M. Kenny, M.A. Lopez-Manchado

Advanced Materials 23, 5229-5236 (2011)

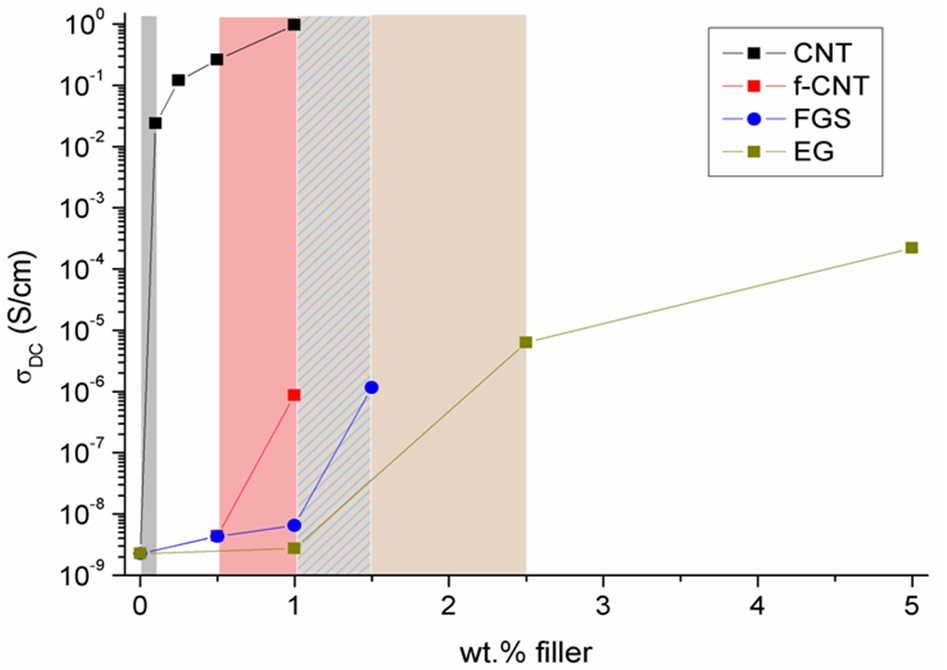

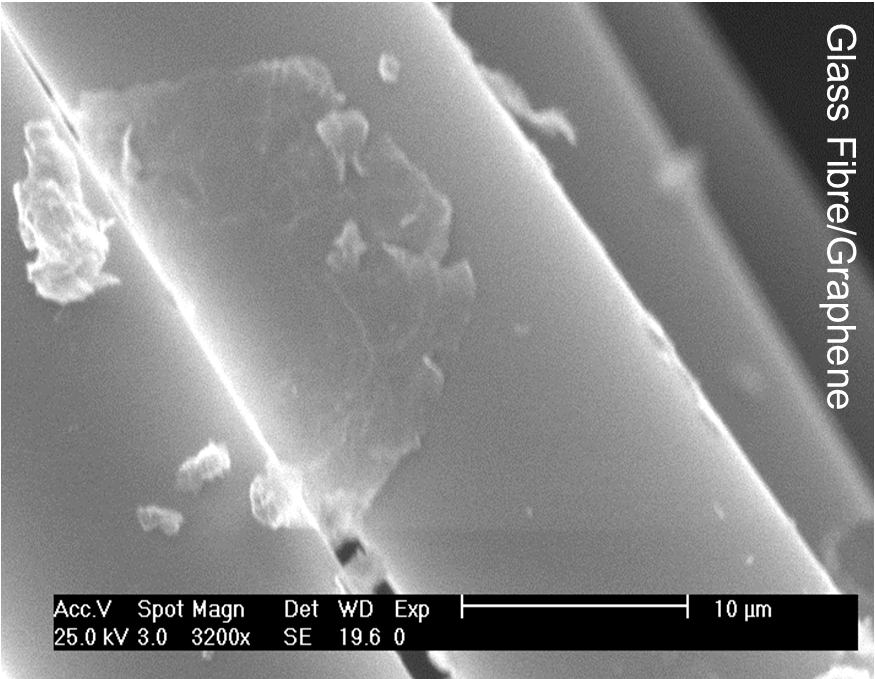

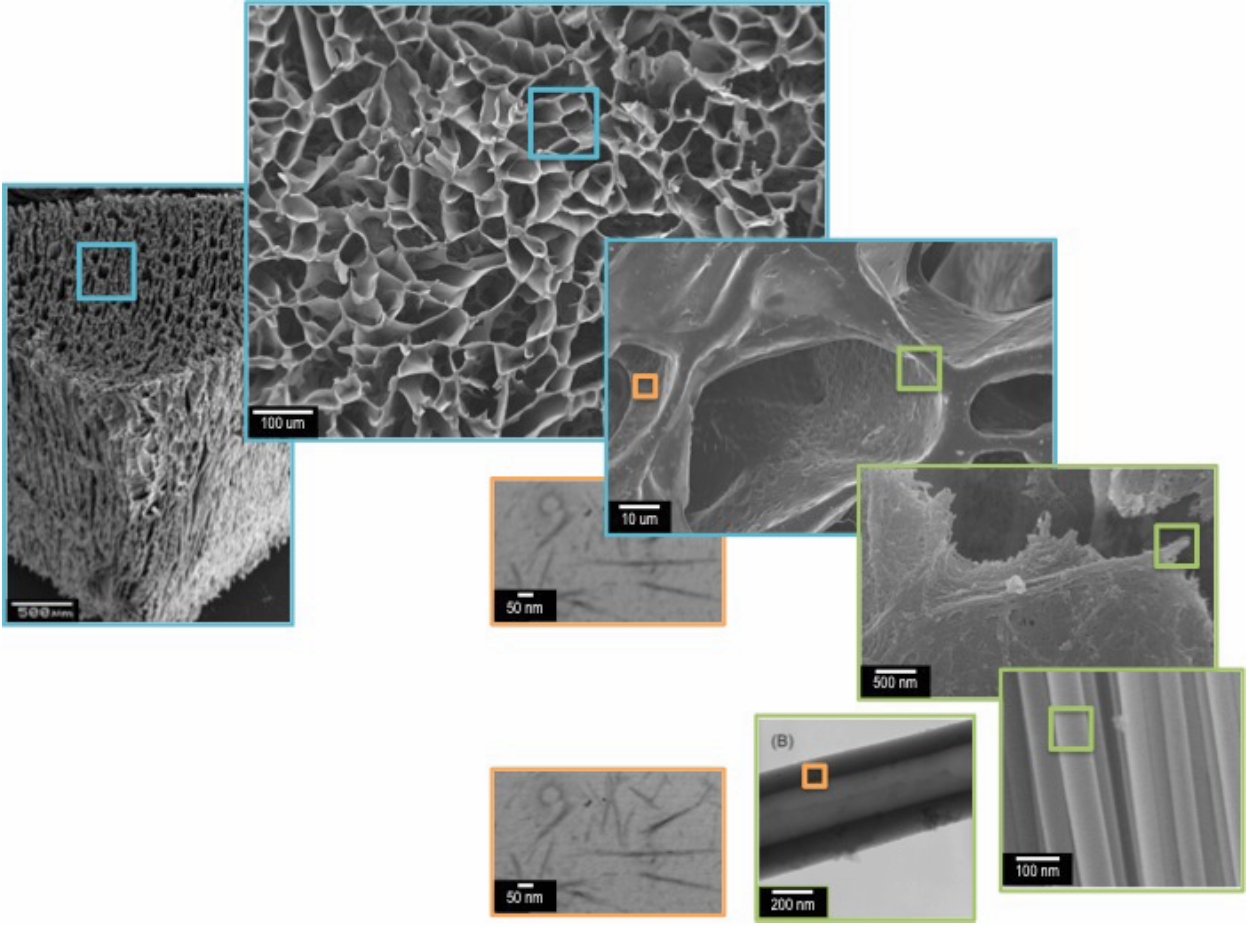

2. Hierarchical composites

Current generation of fibre reinforced polymer (FRP) has extensively been used as structural elements in a myriad of sectors, such as transport and energy, among others. Current technological demands are increasingly stretching their properties to expand their application to more severe or extreme conditions or to extend their life cycle. The objective is to develop the next generation of multifunctional hierarchical FRP via the inclusion of carbon nanoparticles with high mechanical performances, damage sensing capabilities and with self-healing functionality.

The group has experience in the preparation of the laminates by vacuum assisted resin transfer molding (VARTM).

- PhD Thesis: Desarrollo de materiales compuestos jerárquicos basados en fibra de carbono continua y nanopartículas de grafeno

Jose Maria Vazquez Moreno

3. Advanced polymeric electrodes and electrolytes for sustainable energy applications

Stimulated by the need of using large-scale renewable energy sources and to abate CO2 emissions from fossil fuels, the development of environmentally friendly, safe and low-cost energy storage technologies is needed for the establishment of a sustainable society.

The main goal of this research line is the development of polymers with high gravimetric and volumetric charge store capacities, with superior ionic conductivity by following both sustainability criteria in the selection of the functional polymeric precursors and the application of the right synthetic routes and methods for the preparation of highly efficient energy systems. We have developed novel polymers exhibiting charge acceptor and donor units in their macromolecular backbone made from abundant and low cost precursors from biomass and prepared by easier and greener routes such as polycondensation reactions where water was the main reaction by-product. These innovative polymers have been used as electrode and electrolyte material in lithium and sodium ion batteries, supercapacitors and redox flow batteries.

- Polymeric redox active electrodes for sodium ion batteries

N. Fernández, P. Sanchez-Fontecoba, E. Castillo-Martínez, J. Carretero-González, T. Rojo, M. Armand

ChemSusChem DOI: 10.1002/cssc.20170141 (2017) - Full-cell quinone/hydroquinone supercapacitors based on partially reduced graphite oxide and lignin/PEDOT electrodes

A.M. Navarro-Suárez, N. Casado, J. Carretero-González, D. Mecerreyes, T. Rojo

Journal of Materials Chemistry A, 5, 7137-7143 (2017) - Highly-water soluble three redox-state organic dyes as bifunctional analytes

J. Carretero-González, E. Castillo-Martínez, M. Arman

Energy and Environmental Science 9, 3521-3530 (2016)

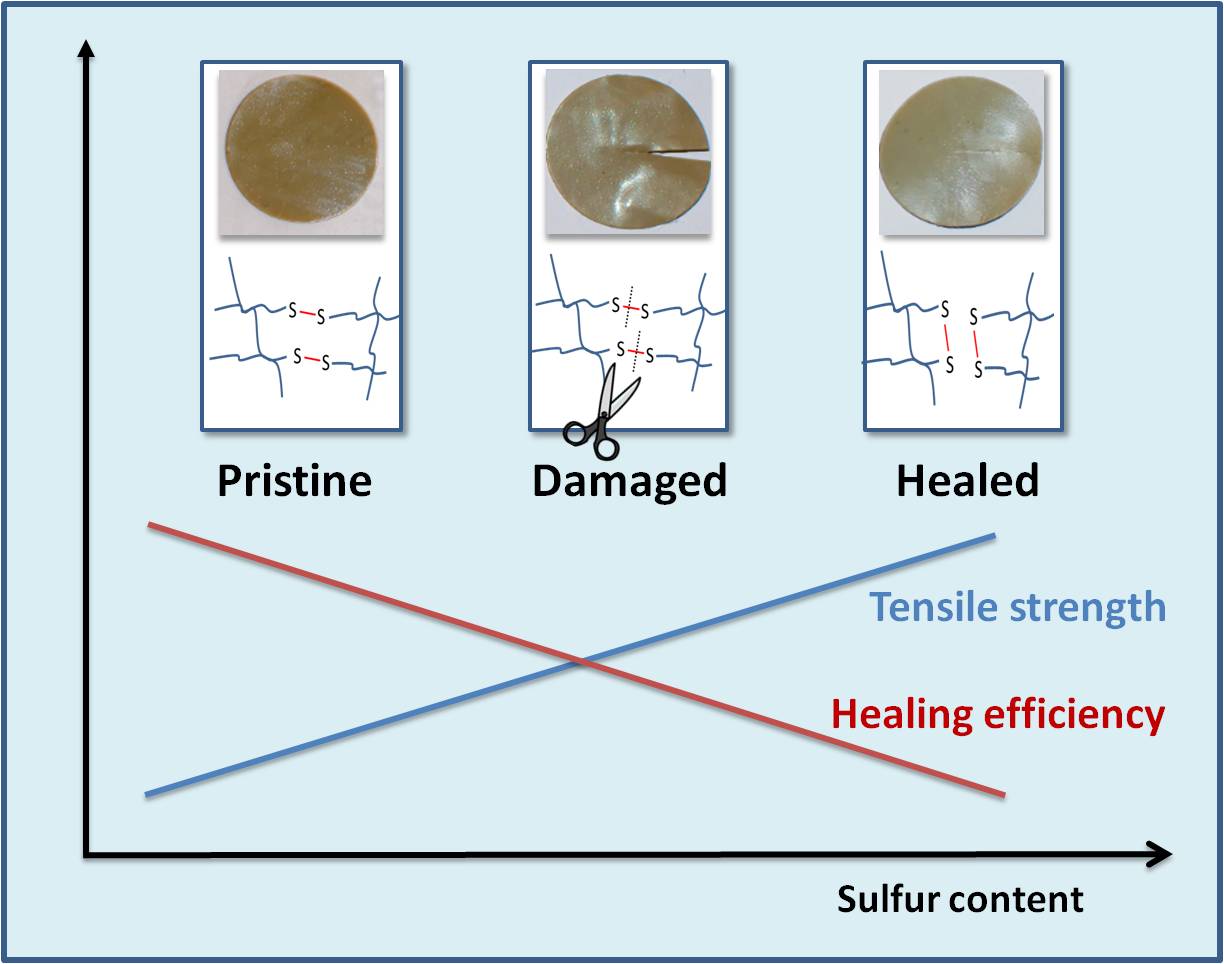

4. Self-healing materials

One of the various problems mankind faces is the waste disposal management. However, this issue can be solved with the design of efficient self-healing materials, in which the regular life cycle of the end product is extended. Self-healing materials seek to enhance the long term durability of a structure by effectively repairing any local micro-, meso- or sometimes even macro- damage which occurs throughout its service life, either through autonomous damage activated processes or by an external trigger.

The main goal of this research line is to develop self-healing elastomers and composite materials. There is typically an enforced trade-off between repairability and mechanical properties, with a high degree of self-healing being achieved with materials having low mechanical strength. The challenge is, therefore, to include fillers of different nature (carbon-based nanofillers and/or waste tire rubber) as to defeat this trade-off. We have so far developed self-healing elastomers with healing efficiencies of more than 80%.

- Effect of graphene content on the restoration of mechanical, electrical and thermal functionalities of a self-healing natural rubber

M. Hernandez, M.M. Bernal, A.M. Grande, N. Zhong, S Van der Zwaag, S.J. Garcia

Smart Materials and Structures 26, 1-10 (2017) - Monitoring network and interfacial healing processes by broadband dielectric spectroscopy

M. Hernández, A.M. Grande, S. van der Zwaag, S.J. García

ACS Applied Materials and Interfaces 8, 10647-10656 (2017) - Turning vulcanized natural rubber into a self-healing polymer: effect of the disulfide/polysulfide ratio

M. Hernández, A.M. Grande, W. Dierkes, J. Bijleveld, S. van der Zwaag, S.J. García

ACS Sustainable Chemistry & Engineering 4, 5776-5784 (2017)

5. Organic conjugated polymer-based functional nanohybrids

This research line aims at the design and fabrication of new nanostructured hybrid materials for electronics in sustainable fashions by implementing processes and products with lower environmental impact and prolonging the lifetime of the devices.

The research line proposes new advanced composite materials based on conjugated polymer nanoparticles or dielectric nanoparticles with carbon nanostructures to develop water based inks of luminspheres (photoluminescent), elecspheres (semiconductor) and dielecspheres (dielectric) nanoparticle solutions to enable the realization of next-generation technologies. The main aim of luminspheres is the preparation of multicoloured photoluminescent nanoparticles for bioimaging, anticounterfeit and lighting. Elecspheres printed under ambient conditions and annealed into an active layer combines the desirable electronic properties of semiconductors (OPVs and supercapacitors), flexibility/robustness of plastics and circumvents difficulties processing sparingly soluble linear semiconductor polymers from solvent at elevated temperature. Dielecspheres can be printed from solution into robust, flexible, high-k dielectric films in device architectures that incorporate a wide range of semiconductor materials and operate at ultra-low voltages (≤1V).

- Superhydrophobic and Highly Luminescent Polyfluorene/Silica Hybrid Coatings Deposited onto Glass and Cellulose-Based Substrates

R. de Francisco, M. Hoyos, N. García, and P. Tiemblo

Langmuir 31, 3718 - 3726 (2015) - Extended conjugation in poly(triarylamine)s: synthesis, structure and impact on field-effect mobility

R.S. Sprick, M. Hoyos, M.S. Wrackmeyer, A.V. Sheridan Parry, I.M. Grace, C. Lambert, O. Navarro, M.L. Turner

J. Mater. Chem. C. 2, 6520 - 6528 (2014) - (N‐heterocyclic carbene)‐Pd catalyzed synthesis of poly(triarylamine)s by Buchwald‐Hartwig coupling of aryl chlorides

M. Hoyos, R.S. Sprick, C. Wang, M.L. Turner, O. Navarro

J. Polym. Sci. Polym. Chem. 50, 4155-4160 (2012)

6. Lightweight polymer foams with functional properties

Polymer foams are found everywhere in our modern world and are used in a wide variability of applications from disposable packaging of fast food, to electromagnetic shielding in aerospace applications.

The group has developed functional foams of different polymer matrixes such as polyurethane, silicone and epoxy resins exhibiting advanced properties such as enhanced fire resistance, excellent thermal and electronic conductivity. Some of this new technology has been patented and licensed. In addition, the group has participated in several national and international academic and industrial projects with companies such as Bayer, Acciona, Grupo Antolin and Repsol. In 2009, the group was awarded the Technological Innovation TALGO prize for our developments in this area.

- Espumas rígidas termoestables conductoras, procedimiento de preparación y utilización

M. Martin Gallego, R. Verdejo Márquez, M.A. López Manchado

P201430094 Consejo Superior de Investigaciones Científicas. - Effect of hard segment content and carbon-based nanostructures on the kinetics of flexible polyurethane nanocomposite foams

M.M. Bernal, M. Martin-Gallego, L.J. Romasanta, A.C. Mortamet, M.A. Lopez-Manchado, R. Verdejo

Polymer 53, 4025-4032 (2012) - Functionalised graphene sheets filled silicone foams

R. Verdejo, F. Barroso-Bujans, M.A. Rodríguez-Perez, J.A. de Saja, M.A. Lopez-Manchado

Journal of Materials Chemistry 18, 2221-2226 (2008)

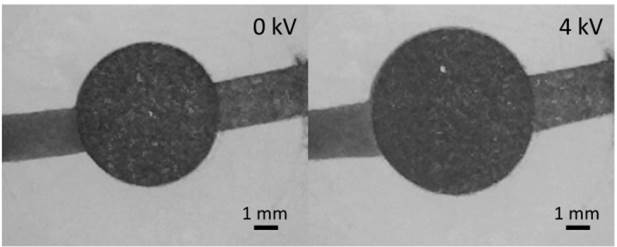

7. Electromechanical actuators (DEAs)

The conversion of electrical energy into mechanical energy by the material’s response to stimuli is crucial in applications such as optics, robotic, prosthesis, sensors and energy.

The aim of the research line is the creation of novel active polymers based on dielectric elastomers, such as silicones, exhibiting a reversible and controllable capacity to respond mechanically to physical stimuli. These low-cost electro-mechanical transducers with high energy efficiency might be used as both actuators and sensors. We have so far developed materials with higher percentage of deformation up to 35 % in comparison with commercial dielectric actuators that shows only 3% deformation when the same electric field is applied. The group has licensed a patent related to this new material´s technology.

- Increasing the performance of dielectric elastomer actuators: A review from the materials perspective

L.J. Romasanta, M.A. Lopez-Manchado, R. Verdejo

Progress in Polymer Science 51, 188-211 (2015) - Actuador de Cristal Líquido Dispersado en Elastómero

R. Verdejo Márquez, L. Jimenez Romasanta, L.I. Mora Valvo

WO 2016/026995, Consejo Superior de Investigaciones Científicas (CSIC), Spain. Under Licence Agreement Option with BraiBook S.L. - Towards materials with enhanced electro-mechanical response: CaCu3Ti4O12–polydimethylsiloxane composites

L.J. Romasanta, P. Leret, L. Casaban, M. Hernandez, M.A. de la Rubia, J.F. Fernandez, J.M. Kenny, M.A. Lopez-Manchado, R. Verdejo

Journal of Materials Chemistry 22, 24705-24712 (2012)